About US

About RightSizeHVAC

RightSizeHVAC is a full service company providing Manual J, Manual D and Manual S services to customers across the United States. We started in 2017 providing Manual J service for HVAC companies in order to attain permits.

Our Approach to HVAC design is Centered Around Learning & Growing With Your Demands

We provide for our clients extensive knowledge of over 5 years of experience in the Manual J industry and 35 years in the HVAC industry.

At HVAC design we provide comprehensive reports in order to attain county permits for your jobs, or get the right size HVAC system for your home

What We Do Best

Manual J

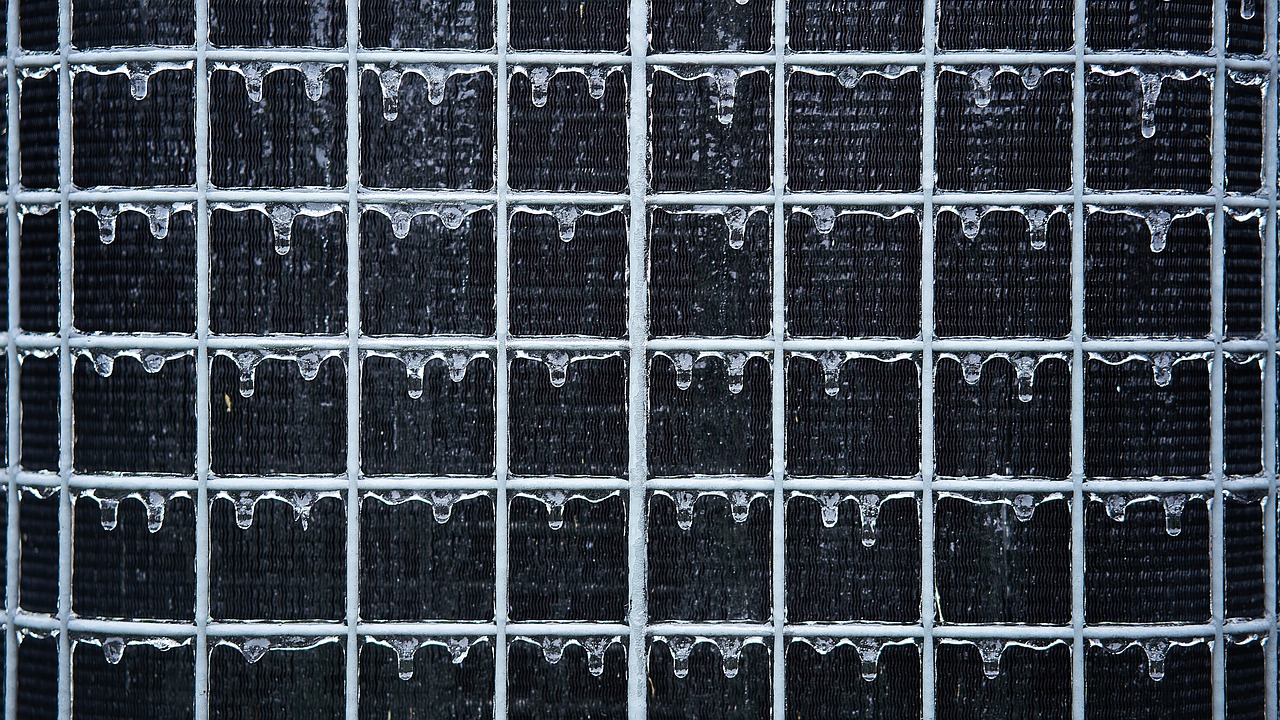

Simply stated a Manual J load calculation factors in the different characteristics of your home (such as square footage, position of your walls, building materials, etc.) to determine how much heating or cooling capacity your home needs. his one is for determining how much heat the house loses in winter and gains in summer. You do this room-by-room for the whole house, which allows you to determine how much conditioned air each room needs for both heating and cooling. It factors in all the surfaces of the building envelope, with their areas and insulation levels. Each wall is given its proper orientation, because windows and doors are attached to them. Other important data include the location and tightness of the duct system, the infiltration rate of the house, the internal loads (appliances and people), and where the house is located.

Manual S

Once you know the amount of conditioned air necessary in each room, you have to select the equipment. What air conditioner, heat pump, furnace, or boiler are you going to install? With forced air systems, this part is critical because every piece of equipment has different characteristics - sensible and latent capacities, the amount of air moved, and the static pressures being the key ones for the next stages. The process of selecting the right equipment for your home. The problem is that most HVAC contractors currently sidestep the Manual S procedure, relying instead on AHRI or nameplate capacity for equipment selection.

Manual D

Finally, once you know how many cubic feet per minute of conditioned air you need for each room, what equipment you're using, and how you're distributing the air in the room, you can design the duct system. Here you look at the location of the air handler, the distance to the ducts, how many turns the ducts have to make, and how much air needs to be delivered. The type of duct has a big impact on the results, as sheet metal ducts have a lower friction rate than flex duct or rigid fiberglass duct board.

Basically, with Manual D, you're trying to balance the delivery of the correct amount of air against the friction rate of the ducts and the static pressures in the system.